The operation of the V & Wedge belts is supremely technical, for ensuring effective material handling. These are the range of extensive belts that operate with the aid of electric motors. These motors have the varied speed to carry its loop, being annexed to rotating wheels. The movement of the rotor wheel generates motion, wherein the conveyor strap moves in one direction, whereas the adjoining loop goes in the direction exactly opposite to it. The architecture of this design makes it necessary for both the wheels to move the same way. In doing so, the movement is facilitated to meet the requirements of various industrial sectors. The belt conveyor mechanism is the most flexible and the least expensive type, implemented in industrial units and also in public transit setups.

Wedge V-Belt is, in general, a gyratory conveyor, having rubber covered around its rollers. The strap gyrates on the top of the roller, so much so that the movement gets it back to the end where it started to roll. The mechanism created by this conveyor strap is implemented at airports for baggage handling. On the other hand, conveyor roller idler offers to roll resistance to the entire mechanism. Choose a service provider who offers minimal rolling resistance, and presents accurate bearing alignment. If you desire to get maximum sealing competence out of your conveyor rolling mechanism then you ought to browse the technical forums on the internet. Doing so can offer you with high assembly precision girdles from providers who have earned reputation in the market space, Select a service provider who has supplied varied types of straps and ancillaries to varied companies.

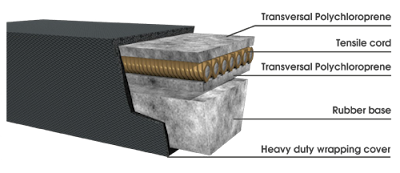

|

V & Wedge Belts |

The sectors and industries which implement the use of conveyor straps comprise of grocery stores, transportation systems, factories, and warehouses with public access. Although the prime benefit of this electric mechanism is to convey products and raw materials from one place to another, it has entered the foray of aiding heavy appliances from being transported from one place to the other. Businesses no longer have to bear undue stress and the time lost due to inefficiency. Both products and raw materials can be safely driven to desired destinations. Its use in the manufacturing industry comes to play in removing manufactured items out of the processing units.

In the Automotive Industries, these Wedge V-Belts play a prominent part in transporting automotive parts from one place to another. The use of these rubber products lessens the risks of worker inflicted with injuries. Their usage in the Warehouses is widespread in offloading outgoing trucks. In shopping malls, Wedge V Belts are implemented in the functioning of a walkalator. Of the myriad of conveyor strap selection, the most popular variants have been the inclined conveyor straps. These designs are renowned for their unmatched quality and low maintenance features. If you desire high performance, you can rely on the food grade girdles which make the best use of the processing conveying system. The mechanisms incorporated in these are sufficient to absorb vibrations and impact resistance.

No comments:

Post a Comment