The original V-belt was developed in 1917 by the Gates Rubber Company. The name V-belt was decided upon due to the V-shaped cross-section of the belt.

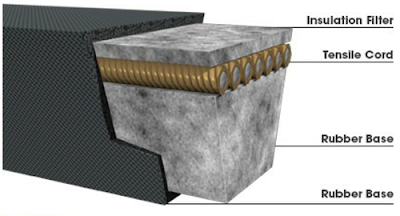

V-belts are also commonly known as Vee belt are a rubber belt with cord members which can be produced in polyester or aramid, steel, Kevlar. The V-Belt has many sections (widths) and can transmit drives for all sorts of equipment such as pumps, building air conditioning, plant and agricultural machinery, grass machinery and lots more applications.

|

V-Belt |

The V shape of the belt sits in a groove in the pulley which stops the V-belt slipping off and keeps it in-line. The V-belt will also tend to wedge into the groove of the pulley as the load increases - the greater the load, the greater the wedging action this improves torque transmission and makes the Vee Belt an effective solution for power transmission.

V-Belts can be purchased in various fixed lengths or in some cases in open length section; these can be joined to make a belt the required length. As well as the original classical wrapped V-Belt, other types such as Wrapped wedge, Cogged Raw Edge, Variable Speed and Banded V Belts are all available.

|

V-belts |

For high-power requirements, banded V-Belts are recommended - two or more V-Belts are joined by a backing/band that keeps them together when running and not allowing the V Belts to slip or elongate within the drive.

For Lawn & Garden Machinery V-Belts that are Kevlar corded and dry cotton wrapped are recommended.

No comments:

Post a Comment